Production Technique Flow

Cleaning is to clean away those unneeded liquid or solid substance attached on the surface of work piece to make the surface clean to some degree. The cleaning progress is the interaction among cleaning solvent, pollutant and surface of work piece, also is a progress involving physical and chemical action. Clean is not only related with the property, type, shape and attachment degree of pollutant, and the physical and chemical property, cleaning performance of cleaning, property and surface situation of work piece, but also with cleaning conditions including temperature, pressure, additional supersonic vibration, mechanical outside force.

So when to choose appropriate cleaning technique, the first is to make technique analysis.

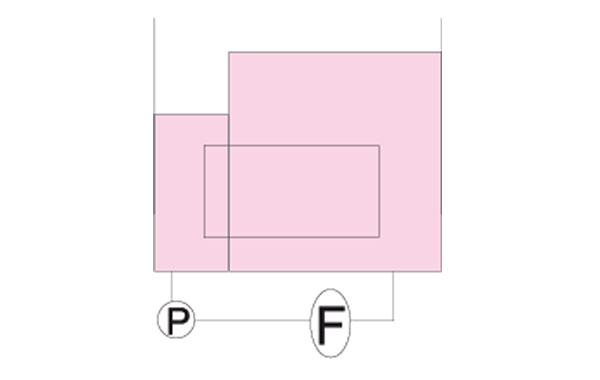

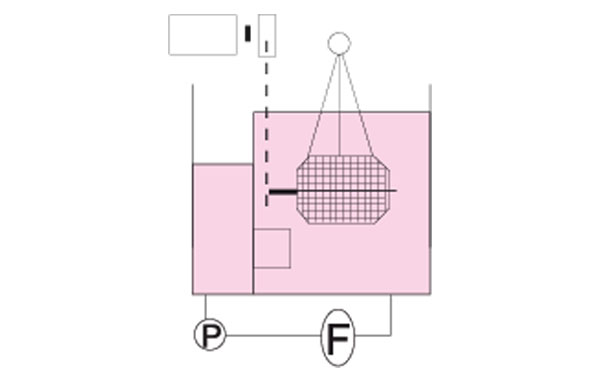

1. Sample A : Aqueous

-

Detergent

Ultrasonic -

City water

Ultrasonic -

DI Water

Ultrasonic -

DI Water

preheating drying -

Hot Air drying

drying (Option)

vacuum drying

2. Sample B : Aqueous IPA

-

Detergent

Ultrasonic -

City water

Ultrasonic -

DI Water

Ultrasonic -

IPA Ultrasonic

IPA steam cleaning -

IPA steam Drying

3. Sample C : Solvent

-

Solvent

Ultrasonic

Primary cleaning -

Solvent

Ultrasonic

Careful cleaning -

Vapour Bath

-

Cooling Dry

-

Solvent Distillation

4. Sample D : Hydrocarbon

-

Hydrocarbon

Ultrasonic -

Hydrocarbon

degassing -

Hydrocarbon

Vaccum cleaning -

Vacuum Drying

-

Vacuum Distillation

| Item/ Cleaning Agent | Aqueous | Solvent | Alcohol | Hydrocarbon | |

|---|---|---|---|---|---|

| Features of cleaning solvent | Cleaning Performance | Weak | Strong | Strong | Strong |

| Cleaning Persistant | Short | Long | Short | Long | |

| Drying | Bad | Good | Good | Good | |

| Flammable | Non | Non | Yes | Combustible | |

| Cleaning cost | Low | High | Low | Middle | |

| Related equipment | Assistant equipment | Pure Water | Distillation Chiller | Gas Detection CO2 | Vacuum Distillation CO2 |

| Cleaning progress | Amount of Tank | Many | Less | Middle | Less |

| Equipment cost | Low | Low | High | High | |

| Environment related law | Method for water pollution | Related | Related | Related | - |

| Fire Fighting law | - | - | Related | Related | |

Technologies

Soaking Cleaning

This method is pouring detergent into washing sink, and soaking objects in it. As only chemical effects of detergent work, the washing result is not good and need cycle deterent for a very long time.

Air Blast Cleaning

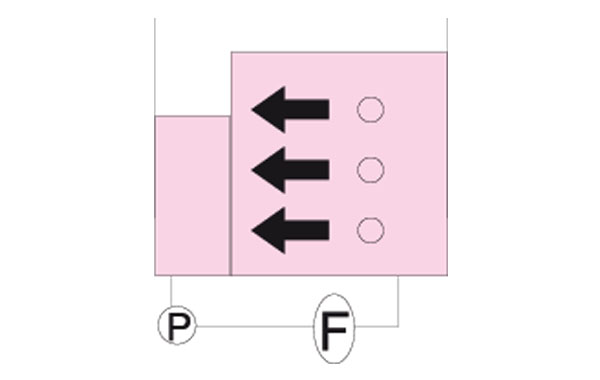

This method is that jet (some) tubes are installed in the tank and detergent is sprayed onto the work piece. The pressure is about 20 kg/cm2.

Jet Cleaning

This method is spraying detergent from the sides of the tank and clean by the stiring force of detergent (physics action). The washing effect is better than soaking clean.

Brush Cleaning

A brush is installed in cleaning chamber. There are special underprops or clips for workpiece. The brush and the mechanic rubbing force would be taken as a primary cleaning while the detergent is soaking and spraying. It can get direct effect.

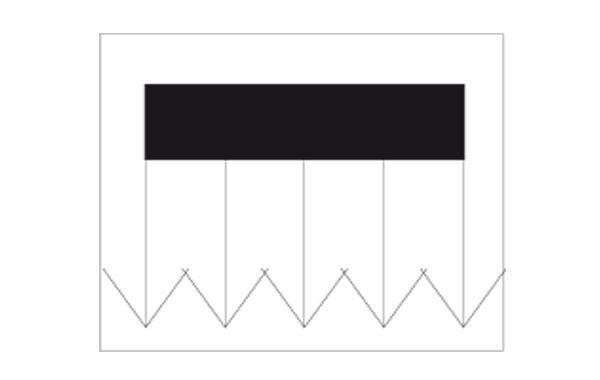

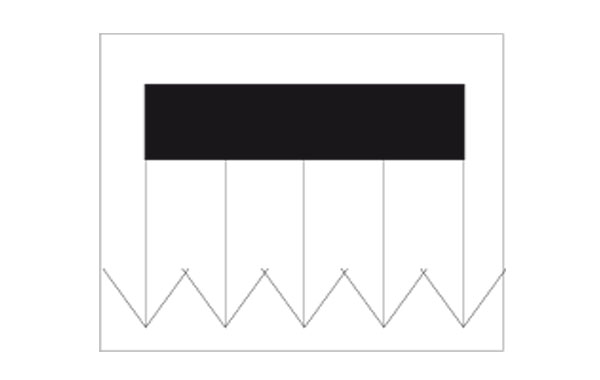

Ultrasonic Cleaning

Install Ultrasonic tranducer to generate Ultrasonic energy (about several thousnad atmosphere pressure), cleaning all pollutant.

Spraying Cleaning

Install spray pipe in cleaning tank. In gas phase spray cleaning agent to the work piece with 2-20 kg/cm2 pressure.

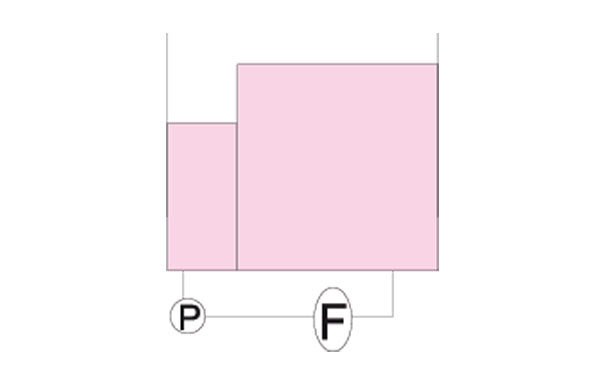

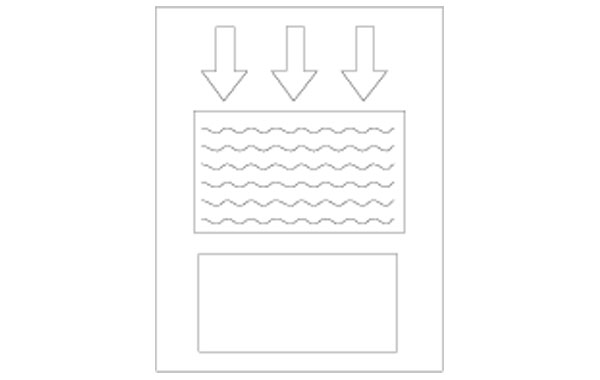

Reducing Pressure Cleaning

Generate negative pressure in cleaning tank. As pressure decreased, cleaning agent can go into the gap between the target and sew. When together used with ultrasonic, cleaning effect becomes better.

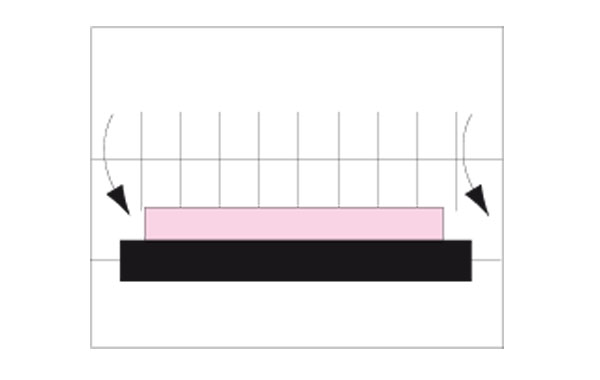

Atomization Cleaning

Install atomize pipe in cleaning tank. In gas state atomize to the work piece with 2-20 kg/cm2 pressure.

Rotate Cleaning

Install rotating equipment in tank. Rotate tube and mix the target at same time. Better effect is to achieved while used together of spraying flow and ultrasonic cleaning.

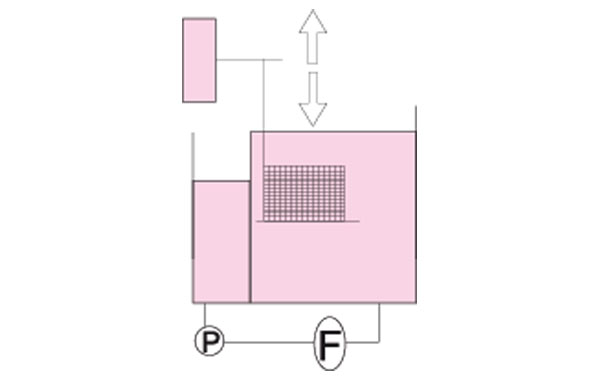

Agitation Cleaning

Install shaking component in tank. Load in the work piece and make in move up and down in cleaning tank. Better effect is to achieved while used together of spraying flow and ultrasonic cleaning.